Industry’s Strongest Connecting Rods for Duramax and Cummins Diesel Engines

Since BoostLine’s introduction to the high-horsepower world, our patented, 3-pocket design connecting rods have powered many different engines across many different disciplines of racing, from drifting to drag racing. With success in testing and development for up to 2,000HP with our connecting rod line for various gas engines, we recognized the need for reliable performance in the performance diesel world.

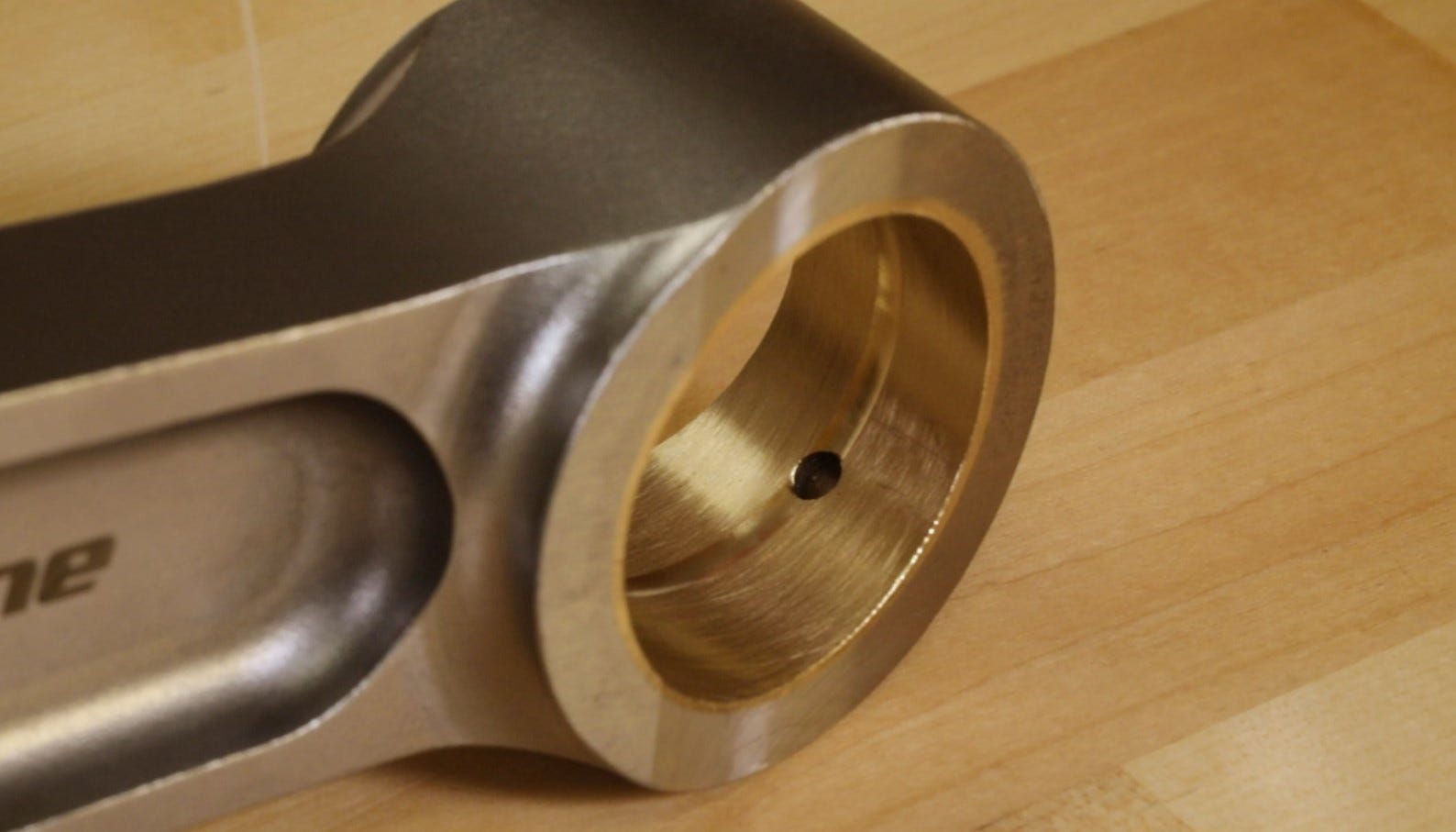

After 18 months of research, engineering, dyno testing, and everything in between, we are proud to announce BoostLine connecting rods specially designed for diesel applications. Launching with GM Duramax 6.6L and Cummins 5.9L and 6.7L offerings, no stone was left unturned in perfecting these rods for use in everything from a stock rebuild to 2,000+ ft/torque wielding race trucks. Forged from 4340 chromoly steel, finish machined, and shot-peened to reduce stress risers, these rods feature BoostLine’s tried and true 3-pocket design adapted for each specific diesel engine.

BoostLine carried over the tried-and-true 3-pocket design and tailored it specifically to each of the Cummins and Duramax applications.

During the engineering process, each BoostLine diesel rod design was subject to complete FEA (finite element analysis), which is advanced computer simulation that allowed us to analyze what kind of stresses the rods would be subject to under operating conditions and account for those before going into manufacturing. Once designs were fine-tuned, we manufactured test batches and checked them in our QC lab on our CMM equipment for precise specifications before subjecting them to real world testing. In fact, this process was carried to every rod that goes out the door on its way to the customer. Each individual rod goes through a 25-point CMM inspection and all measurements are recorded on a BoostLine inspection card and provided in the box with the rods.

Each BoostLine diesel rod is subject to a 25-point CMM inspection in our in-house quality lab. Each critical dimension is checked and recorded onto a specification sheet provided with each set of BoostLine diesel rods.

Test rods were installed into each of the diesel engine applications and put on an engine dyno. After a sinusoidal break-in, we ran the engines through a 50-hour endurance test where BoostLine diesel rods were subject to up to 2,100 lb⋅ft of torque. Afterward, the engines were disassembled and the rods were put back on the CMM to compare to the benchmark specifications and dimensions of the pre-test measurements and design. After inspection, all our test rods were well within tolerances in all critical areas measured.

We partnered with S&S Diesel to performance extensive strength and endurance dyno testing. After testing, we tore the engines down and measured each critical dimension on our in-house CMM. Every new BoostLine diesel rod is measured and recorded onto a specification sheet provided with each set of BoostLine diesel rods.

Specifically, there were several key factors we kept an eye on after endurance testing, including roundness of the big end and small ends as well as rod twist. The load created from the inertia of heavy, diesel pistons can create problems in these areas with OEM or less robust aftermarket rods. Thanks to the proprietary, 3-pocket design, BoostLine rods benefit from the strength characteristics of H and I-beam designs while keeping weight satisfactory.

Post-endurance testing inspection had a special focus on bore roundness and rod twist, both of which well-exceeded allowable tolerances.

Attention to detail doesn’t stop there. BoostLine diesel rods utilize ARP 2000, 12mm fasteners for the rod caps. These bolts provide a higher clamping load, allowing the big end to stay round during increased engine RPM where natural force is trying to stretch the rod cap. These are strong bolts in a small package, which provides additional benefit with ease of installation. Rods fitted with larger bolts make it very difficult to install through the cylinder, but the 12mm bolts deliver the best of both worlds.

The 12mm fasteners provide a uniquely beneficial combination of clamping force and ease of rod installation.

BoostLine diesel rods for Duramax engines also feature a tapered pin end design, allowing them to be used with a wide range of pistons, from OEM to fully custom.

To protect them when they’re on their way to you, BoostLine diesel rods are packaged and shipped in boxes with custom-cut foam inserts and a vacuum-sealed layer of protection.

BoostLine diesel connecting rods proudly bring you industry leading strength at industry leading value. Current BoostLine diesel rod applications include:

| Engine | Year | Part Number | Length | Retail Price |

| GM Duramax 6.6L | 2001 – 2012 | GM6418-358 | 6.418 in. | $2,173.59 |

| Cummins 5.9L & 6.7L | 1989 – 2012 | DO7559-575 | 7.559 in. | $2,010.57 |

Have a question or want to get a set ordered?

Give us a Call at 1-800-321-1364